Quality Policy

Parma Stamp has always placed emphasis on quality, both in terms of overall customer satisfaction in terms of intrinsic quality of the product. The company’s policy gives priority attention to detail, precision tolerances, compliance with the requirements of the technical design of the commission of the customers. No coincidence that all staff is trained to follow internal procedures aimed at containing the error or possible variations from the requirements. The absolute respect of the customers’technical requirements represents for us the loyalty to the client, which must be assured of a totally reliable supplier. Parma Stamp historicizes its production cycle via barcode for optimal availability of the products; for each tool are created a card processing, a control cycle, certificate of steel raw materials and certification of the heat treatment. Essential by the achievement of a comprehensive quality are their timely delivery and flexibility in our ability to adapt ourselves to the needs of our many customers and all the new ones who will want to rely on our experience of over forty years of success. The customer is a very important resource TO Parma stamp; we believe that make our customers loyal to us is the hardest task that drives us to continuous improvement. We do not consider us never arrived, but realize that as much as we did, the same we can progress. In the era of globalization we want that our customers view us as their partner in bending sheet metal, eliminating geographical , cultural and linguistic barriers.

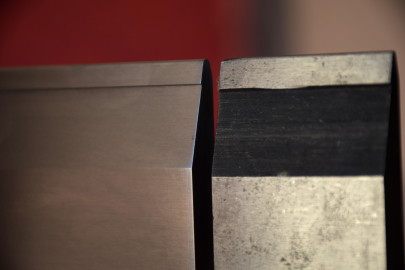

New customers vey often do not know us and our quality so they are not able to distinguish Parma Stamp’s quality from its competitors’ one. We would like therefore to recall your attention to such important details, as the precision of the tolerances, which respects the technical drawing, and the good looking of the finishings. As you can notice yourself by clicking and enlarging the pictures, the one on the left hand side is a tipical Parma Stamp’s die whereas the one on the right is an average example of our competitors’ finishing which is available on the market.

If we would like to resume this features in a comparative chart we could state that:

Parma Stamp: mirror-like grinding, very tidy chamfers, frontal sectioning made by ground surface for a perfect matching of the square and the sectioned pieces, completely ground V-opening.

Competitors: very rough ground surface, imprecise chamfers made by hands with a file, frontal surface not ground but just milled, so less precision in the square and matching of the sectioned set, V-opening is ground just on the upper part.